Today, boxer engines are most often installed in motorcycles and aircraft. Of the automakers, only Subaru persists in using them, and there are many admirers of their WRX sports cars. The question arises as to why the Japanese are so obsessed with them. The Indy Auto Man mechanics reveal the pros and cons of horizontal-opposite engines in modern vehicles.

Subaru Boxer Engines

The history of compact, technologically advanced, and highly efficient horizontally opposed engines in Subaru production cars began in 1966, and goes all the way to WRX sports cars. The first engine of this configuration was the Subaru 1000. The very first Subaru boxer was a four-cylinder, water-cooled. With a displacement of 980 cc, it developed a maximum power of 55 hp at 6,000 rpm. The combination of a boxer engine with innovative front-wheel drive provided the Subaru 1000 with outstanding handling and stability on the road. The natural balance of the boxer engine avoided increased vibration, and the low center of gravity of the power unit provided the car with increased road stability.

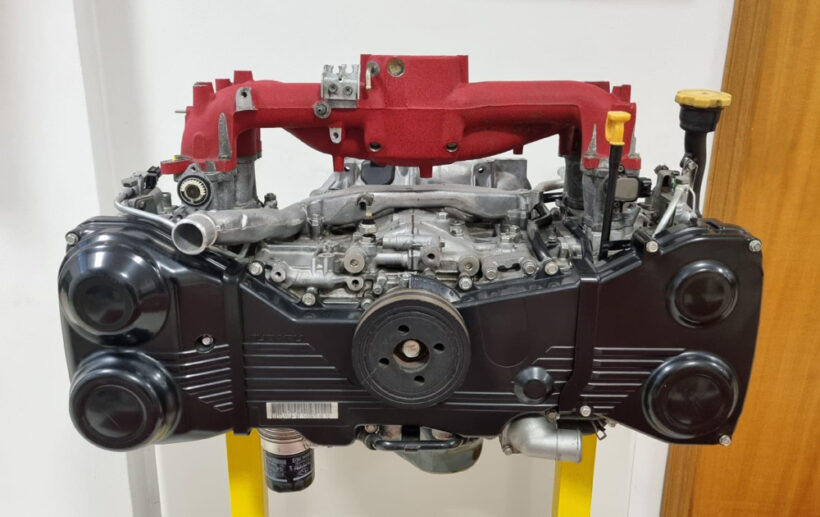

And these days, Subaru stays true to the chosen pattern. That is why all Subaru cars of the current model range are equipped exclusively with gasoline 4-cylinder horizontally opposed Subaru Boxer engines. These engines have several advantages inherent in the design itself:

Flat block

In an opposed engine, the cylinders are located horizontally – symmetrically, on both sides of the crankshaft. Instead of the usual vertical blocks of in-line engines and V-shaped cubes, the boxer looks like a suitcase, opened and laid flat. Hence, its first advantage is its low height and, as a result, a low center of gravity. This was precisely the main advantage of the boxer car for many years – it was low-mounted and promised a noticeable gain in stability when cornering.

The horizontally opposed power unit also improves the passive safety of Subaru models: in a serious impact, such an engine moves much more easily under the bottom of the car, protecting the driver and passengers in the cabin from the destructive effects. And the additional space under the hood allows reducing the impact of a possible collision.

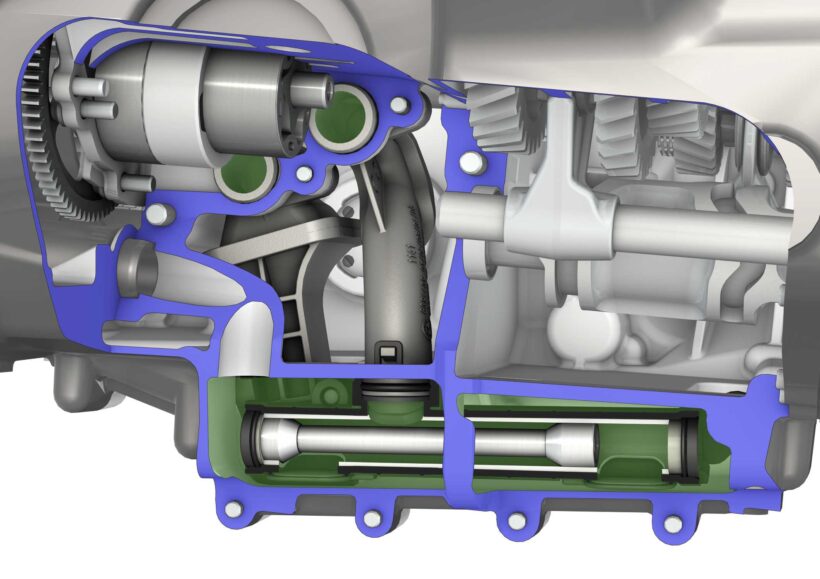

Mutual balancing

The next advantage comes from the design of the motor. The pistons with the connecting rods are arranged in pairs and directed in diametrically opposite directions (that’s why the engine is called “opposite”). During operation, the pistons in pairs move in opposite directions. It turns out that they balance each other without any additional tricks or devices. These engines have neither balancer shafts nor crankshaft balancers themselves. The benefits are reduced losses due to the rotation of excess mass, compactness of the power plant, its speed, and high torque.

And here, the advantages of opposites end, and the disadvantages begin.

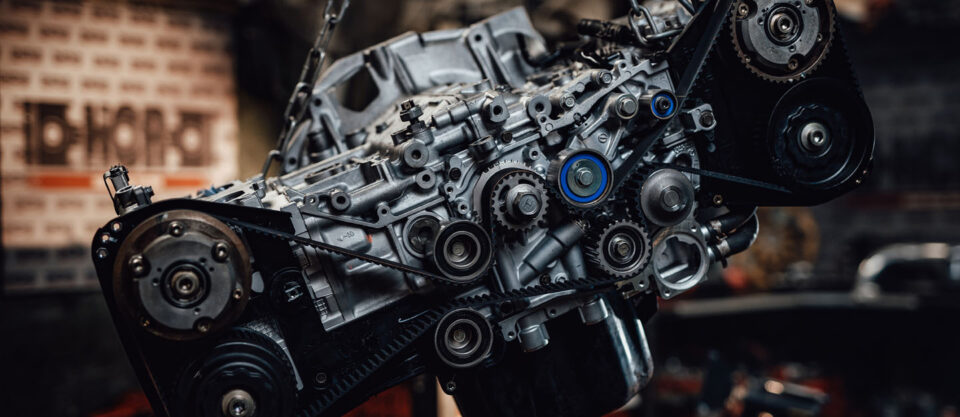

Design complexity

The first drawback, oddly enough, follows again from the design of the motor. There is no single cylinder block but two half-blocks with the crankshaft sandwiched between them. The procedure for installing it is quite a circus. Why are we talking about installation? Unfortunately, these motors are not reliable. There are also two cylinder heads and two branches of the cooling system. The slightest discrepancy in their symmetry — and it’s time to go to the master, who will begin to curse at the sight of the number of pipes.

High Oil Consumption

Horizontal cylinders of any engine are always accompanied by an inherent problem: the engine oil cannot flow down as easily as in in-line or V-shaped ones. But Subaru engines love to consume oil not only for this reason. The difficulty with uniform cooling of widely spaced cylinders very often leads to their rapid wear due to the warping of the engine internals.

Bulky

For about three-quarters of the 20th century, Volkswagen was the pioneer of boxer cars, but even the Beetle’s modest 1-liter engine could hardly fit between the rear wheels of the legendary car. The Subaru’s boxer has acquired a water jacket, turbocharging, overhead camshafts, and added in volume. It remained more or less flat, but it expanded greatly in width, taking up all the space between the side members. So much so that in some versions, you have to at least lower it down to replace spark plugs. For designers, this point creates many problems, since the car must have a fairly wide engine compartment.

Poor adaptation to SUV needs

No matter how flat the boxer pan is, it is there because the oil in the engine still needs to drain somewhere. When the car rolls seriously, a deeper sump is always needed and on a boxer engine, this is especially critical since there is a high risk of oil leaking into the horizontal cylinders. But it is also impossible to move the pan down too far — the ground clearance will decrease. There is only one way out – to raise the engine up, which was done, for example, on the Tribeca. However, this solution resulted in a high center of gravity, deteriorated stability, and layout problems in the engine compartment.

The list of issues with boxers is quite long. This is the difficulty of manufacturing many parts of semi-blocks, the tightness in the engine compartment under the heads due to the small space for exhaust manifolds and catalysts, and the uniqueness (and therefore high cost) of many engine components and the layout uniqueness of the front part of the car itself, due to the unusual shape of the motor… What is the result? Today’s opposed aircraft are the domain of light aviation, where compact dimensions, air cooling, and a love for engineering masterpieces make them in demand. Or in big sports, where all the same qualities of boxers are indispensable for Formula 1. In the practical world of mass automobile production, boxers are more of a club of interests than a financially justified decision. This is a tribute to a beautiful tradition and a legend that attracts a narrow class of owners with its unusual sound of operation, non-standard design, and the feeling of belonging to a select caste.