Precision and efficiency are of utmost importance in the realm of automotive manufacturing.The ability to transform a concept into a tangible product requires advanced techniques and technologies. One such technology that plays a crucial role in the automotive manufacturing process is CNC machining.

Computer Numerical Control (CNC) machining has revolutionized the way automotive components are designed, prototyped, and produced. In this article, we will explore the significance of CNC machining in the automotive industry, particularly in the journey from prototyping to production.

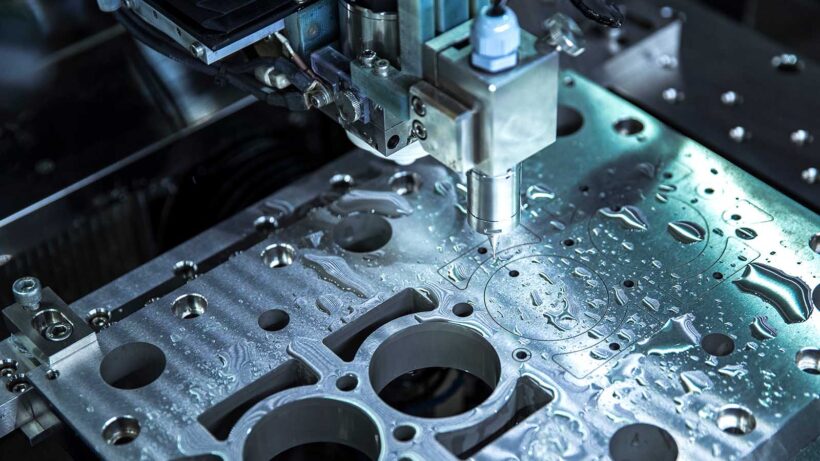

The Basics of CNC Machining

CNC machining is a technique where precise and intricate parts are created by selectively removing material from a solid block using computer-controlled machines.The process starts with a 3D computer-aided design (CAD) model, which is translated into machine-readable instructions. These instructions guide the CNC machine to precisely cut, drill, and shape the material according to the desired specifications.

Automotive Prototyping with CNC Machining

Prototyping is a crucial phase in automotive manufacturing, allowing engineers to validate designs and make necessary adjustments before moving into full-scale production. CNC machining plays a pivotal role in this stage, enabling the creation of prototypes with high accuracy and speed. By using CNC machines, automotive manufacturers can transform digital designs into physical prototypes, ensuring that all components fit together seamlessly and meet the required specifications. The ability to rapidly produce prototypes through CNC machining allows for faster iteration and optimization of designs, reducing development time and costs.

Complex Component Manufacturing

Modern automobiles consist of numerous complex components, ranging from engine parts to intricate interior features. CNC machining is instrumental in manufacturing these components with precision and consistency. By utilizing multi-axis precision cnc manufacturing, manufacturers can produce intricate geometries, such as turbine blades, complex engine blocks, and transmission components. The flexibility and versatility of CNC machining enable automotive manufacturers to create parts with tight tolerances, ensuring optimal performance and reliability.

Production Line Efficiency

Once the prototyping phase is complete and the design has been finalized, automotive manufacturers shift their focus to mass production. CNC machining plays a critical role in achieving efficient production lines. The use of CNC machines in large-scale production ensures consistent quality, as each part is manufactured with the same precision as the initial prototype. The continuous operation of CNC machines reduces downtime and maximizes productivity. The automation and repeatability of CNC machining eliminate human error and deliver parts that meet the stringent requirements of the automotive industry.

Material Selection and Versatility

Automotive manufacturers work with a wide range of materials, each with its own unique characteristics. CNC machining offers unparalleled versatility in material selection, allowing manufacturers to work with metals, plastics, composites, and more. Whether it’s aluminum for lightweight components or high-strength steel for structural parts, CNC machining can handle a diverse range of materials, ensuring the production of robust and durable automotive components.

Cost-Effectiveness

Cost considerations are a significant factor in automotive manufacturing. CNC machining provides a cost-effective solution for producing automotive parts. The ability to automate production processes and optimize material utilization reduces waste and lowers production costs. Additionally, CNC machines can operate for extended periods with minimal supervision, reducing labor costs associated with manual machining operations. The speed and efficiency of CNC machining also contribute to overall cost savings by accelerating the production timeline and bringing products to market faster.

Future Trends and Advancements

The field of CNC machining is continuously evolving, with advancements in technology driving further innovation in automotive manufacturing. One such trend is the integration of additive manufacturing techniques, such as 3D printing, with CNC machining. This combination allows for the production of highly complex parts that were previously challenging to manufacture. Additionally, the use of artificial intelligence and machine learning algorithms in CNC machines enhances process optimization, predictive maintenance, and quality control, further improving the efficiency and accuracy of automotive component production.

Conclusion

CNC machining has become an integral part of the automotive manufacturing process, playing a vital role from prototyping to mass production. The precision, speed, and versatility offered by CNC machines enable automotive manufacturers to create complex components with tight tolerances, ensuring optimal performance and quality. The cost-effectiveness and efficiency of CNC machining contribute to streamlined production lines and faster time-to-market. As technology continues to advance, CNC machining will remain a driving force in automotive manufacturing, shaping the future of the industry.