In the ever-evolving landscape of automotive manufacturing, the pursuit of efficiency and cost-effectiveness is a constant. With the global injection molding automotive industry boasting an estimated worth of $261.8 billion in 2021, it’s evident that businesses are seeking innovative methods to meet their production demands while ensuring the highest quality standards.

The Evolution of Automotive Injection Molding:

Understanding the Essence:

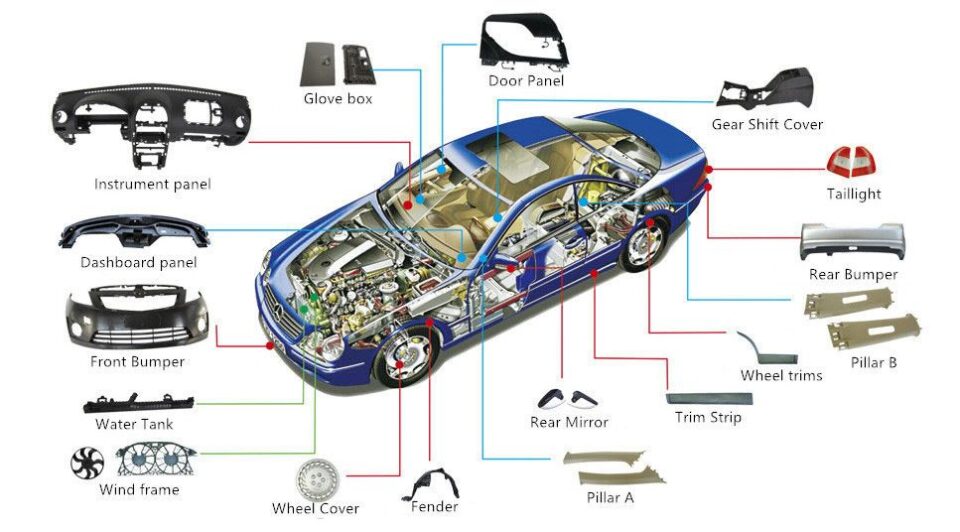

Automotive injection molding emerges as a pivotal player in this narrative. It’s a manufacturing process that relies on high-pressure plastic injection to craft a diverse range of automotive components. From the robust body panels to the intricate interior elements and critical engine parts, automotive injection molding has become a linchpin for manufacturers worldwide. Its widespread application in both Original Equipment Manufacturer (OEM) and aftermarket sectors underscores its versatility and reliability.

The Intricacies of the Process:

At its core, the process involves the careful melting of plastic resin, injection into a precision-machined mold under high pressure, and subsequent cooling and solidification of the material. The ballet of polypropylene, ABS, nylon, and specialized plastics results in the creation of durable parts boasting not only complex shapes but also intricate designs critical for modern automotive applications.

The Strategic Advantages of Injection Molding:

1. Cost-effectiveness:

One of the hallmarks of injection molding is its unparalleled cost-effectiveness. As one of the most preferred manufacturing processes in the automotive industry, it excels in rapid production rates. Moreover, the process significantly reduces material wastage, a financial boon for businesses aiming to balance cost-effectiveness with high-quality production. The investment in injection molding machinery becomes a strategic move, enabling automotive companies to gain a competitive edge.

2. Speed:

Time is a valuable commodity, especially in the fast-paced automotive industry. Injection molding addresses this need with automated machines and computer-guided processes that streamline production. The efficiency gained not only boosts overall productivity but also aids in keeping costs in check, a crucial aspect in the fiercely competitive market.

3. Quality Assurance:

In an industry where precision is paramount, injection molding stands as a guarantor of quality. The process ensures consistently high-quality output through precision molding techniques, resulting in parts with uniform thickness. The tight tolerances maintained in these techniques guarantee that each part meets or exceeds industry standards, providing a foundation for reliable and superior automotive manufacturing.

4. Durability:

The longevity and durability of automotive components are critical factors in the selection of materials. Plastics like ABS and polypropylene, commonly used in injection molding, showcase exceptional strength and resilience. These materials endure harsh conditions, making them ideal for the rigors of automotive applications. Their ability to withstand different temperatures and resist breaking ensures the longevity of vehicles, contributing to their overall robustness.

5. Design Flexibility:

Breaking away from the constraints of traditional manufacturing, injection molding grants automotive companies unprecedented design freedom. Experimentation with the size and shape of various components becomes not only possible but also encouraged. This flexibility transforms once-impossible designs into tangible components, opening avenues for innovative automotive aesthetics and functionality.

6. Versatility Across Vehicles:

The reach of automotive injection molding extends far beyond the production of a specific type of vehicle. Its unmatched versatility allows for the manufacturing of components and fixtures for a diverse range of vehicles. Whether it’s classic cars, coupes, sedans, boats, or airplanes, injection molding technology proves its adaptability. From exterior features like grilles, bumper covers, and wheel flares to entire interior design systems, the scope of application makes automotive injection molding an indispensable process for efficient vehicle production.

Deciphering the Automotive Injection Molding Process:

From Concept to Reality:

The automotive injection molding process is a well-established and streamlined journey that offers numerous benefits to car manufacturers. The initiation involves creating a virtual model of the desired part using Computer-Aided Design (CAD) software. This virtual blueprint then transforms into a physical mold that serves as the vessel for injecting molten material.

High-Pressure Precision:

The heart of the process lies in injecting the molten material into the mold under high pressure. This ensures the material takes the exact shape defined by the mold. Once injected, the material undergoes a cooling process until it solidifies, forming the desired part with precision. Specialized machines are then employed to eject and collect the parts, preparing them for the subsequent assembly or additional finishing processes.

The Role of Technology:

It’s essential to highlight the role of technology in modern injection molding. The use of CAD software not only aids in the design phase but also contributes to the precision and repeatability of the process. Advanced machinery and computer-guided systems further enhance the efficiency and accuracy of injection molding, making it a cornerstone in contemporary automotive manufacturing.

The Future of Injection Molding in Automotive Manufacturing

Embracing the Potential:

In conclusion, automotive injection molding emerges as a beacon guiding the industry towards efficient and cost-effective mass production of plastic parts. With the right materials and equipment, businesses can forge high-quality components that are not only cost-effective but also efficient in meeting the ever-growing demands of the automotive market.

Ready to Take the Leap?

If the realm of automotive injection molding aligns with your business needs, there’s no better time than now to explore its possibilities. Feel free to contact us today for a personalized consultation. Our team is ready to provide free custom quotes, facilitating the transformation of your vision into a tangible reality.

The Road Ahead: A Glimpse into the Future of Automotive Manufacturing:

Innovations on the Horizon:

As technology continues to advance, the future of automotive injection molding holds even more exciting prospects. Innovations in materials, design methodologies, and manufacturing processes promise to further enhance the efficiency and sustainability of injection molding. From eco-friendly materials to advancements in automation, the roadmap ahead points towards a greener, more streamlined future for automotive manufacturing.

Global Impact:

The global impact of automotive injection cannot be overstated. Beyond its direct influence on the automotive industry, the advancements in injection molding technology have far-reaching implications. The efficient production of durable, high-quality components ripples across sectors, contributing to the overall advancement of manufacturing practices on a global scale.

Educating the Industry:

As advocates for the industry, it’s crucial to recognize the role of education in shaping the future of automotive injection molding. Knowledge dissemination about the benefits, innovations, and best practices in injection molding ensures a collective progress that benefits manufacturers, consumers, and the environment.

Final Thoughts: Charting a Course for Excellence in Automotive Injection Molding:

As we navigate the intricate landscape of automotive manufacturing, the significance of injection molding becomes increasingly apparent. It’s not merely a manufacturing process; it’s a catalyst for progress, efficiency, and innovation. Whether you’re a seasoned player in the automotive industry or an emerging force, embracing the potential of automotive injection molding is a strategic move towards a future where precision meets sustainability, and efficiency is the driving force behind every production line.