Trucks are an essential part of daily life. You’ll see them cruising back and forth along the highway and often not give them a second thought. Yet, without these trucks, the items you purchase in the shops wouldn’t be there.

Despite advances in various technologies, trucks are still the most dominant force in freight distribution across the country.

Whether you’re a truck operator, owner, or driver, you need to know the most common causes of truck breakdowns and be prepared for them. Regular maintenance and the skill of a good automotive electrician such as sydneytruckelectrical.com.au can help reduce the number of breakdowns. But, sometimes these things simply happen and you have to be ready to deal with them.

That means having a spare truck ready to take the load and do the drop, or perhaps paying a rival company to do it for you.

Let’s take a look at the 6 most common causes of truck breakdowns

1. Flat Tires

If you get a flat on your car you jack it up and replace it. While this can take you anything from 10-30 minutes it’s a minor inconvenience and you’re on your way again.

It’s different when you’re driving a truck. Firstly, the truck is significantly heavier, making it difficult to carry a jack capable of lifting it. Secondly, you need to consider where the tire is, how you’re going to get to it, and whether you have enough spares to cover it. Trucks have a lot of tires.

The situation is made even more complicated when you’re in the middle of a desert section. Waiting for a tow truck can take hours and you may have a load that needs to get somewhere.

What may surprise you is that 50% of all truck breakdowns are tire-related. Inspecting the tires before you start your journey, specifically making sure they are nit underinflated or that the tread is worn, can reduce the likelihood of a tire going flat.

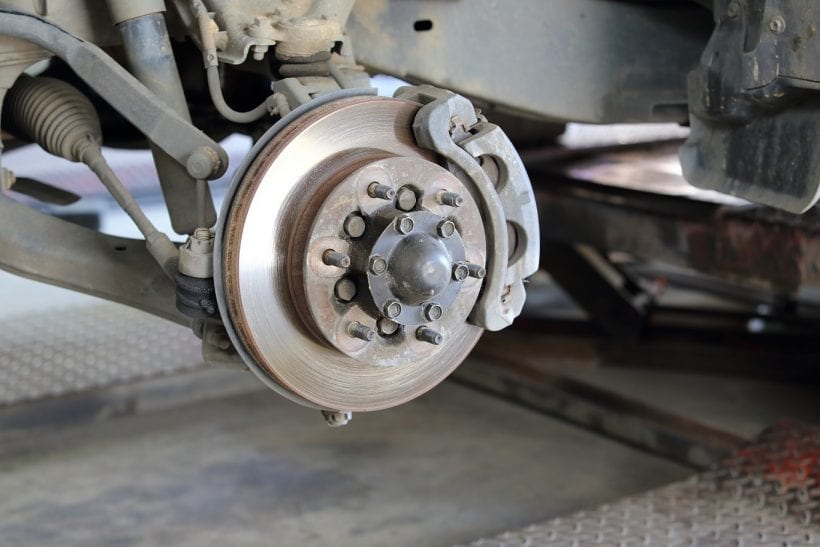

2. Brakes

This is fortunately not a common issue but it is a concerning one. Brake failures lead to accidents that can be particularly nasty.

A truck has to deal with immense forces when braking, this creates an impressive level of heat and friction on the brake pads and discs. If they are not properly maintained its inevitable that they will fail. The question simply becomes when?

T’s not just the pads and discs that can cause issues. The hydraulic fluid may be leaking thanks to corrosion in the pipes, water may have contaminated the fluid, or air could be getting into the system. Checking and maintaining the brakes properly is essential.

3. Refrigerated Trailer

If you’re hauling a temperature-sensitive load you’re going to need a refrigerated trailer. Of course, these trailers work hard to keep the temperature correct in a variety of conditions. To ensure they don’t fail on you it’s essential to monitor them regularly and have a technician keep an eye on all the components. You need this to be working efficiently If it’s not and it fails you’ll have a very limited opportunity to replace the truck and get the goods where they need to be.

If the goods are spoiled it can be a large financial concern, you’ll need to have the right insurance to cover the risk associated with hauling temperature-sensitive items.

4. Electrical System

Modern trucks have a much greater reliance on electrical systems From simple items like power steering to more complicated items such as the central computer, electrics can and do fail, leaving your truck stranded on the roadside.

A good automotive electrical technician will be needed to diagnose the issue and resolve it. In some cases this is possible at the side of the road, it will depend on what fault has occurred.

The main issue with electronics is the complexity of a modern truck. There are sensors for everything, just one faulty sensor can make the truck run badly but it can be difficult to trace the right sensor.

As well as regular maintenance it’s essential that you be aware of the signs of an impending electrical issue. For example, flickering or dimming lights suggest a power output issue. That could be enough to shut down the power supply to the truck, preventing it from starting or running.

Electrics are complicated and best left to an expert!

5. Cooling System

The cooling system is essential to your truck. It allows the engine to run. If the cooling system fails the engine temperature rises reducing efficiency. After it reaches a certain point the heat produced by the engine will not be dissipated. The result is potentially a warped head and engine damage.

The most common issues with the coolant system are the sudden failure of a pipe. Regular inspection will reduce the likelihood of this happening

6. Fuel

Finally, the fuel is the lifeblood of your truck. Without it, the truck simply can’t run. The simplest issue with fuel is to run out. This may seem absurd but it’s easy to miscalculate the distance to the next fuel stop, especially when you’re covering vast distances.

Another common fuel issue is the pump itself. Failure of this will result in no fuel delivery to the engine and the truck will not be able to move. Unfortunately, this will require replacing the fuel pump, something that can be done at the roadside if you have the available part.

Final Thoughts

The key to avoiding most truck breakdowns is to do regular maintenance. This should pick up any issues before they become a problem and allow them to be fixed or for you to be prepared for something to break.

Of course, there will always be times when the truck breaks down without warning. You should have a contingency plan in place to help you deal with this eventuality and keep the load going where it needs to.

Trucks travel huge distances and are subject to a lot of different stresses, having an automotive technician available to help is beneficial and reassuring.