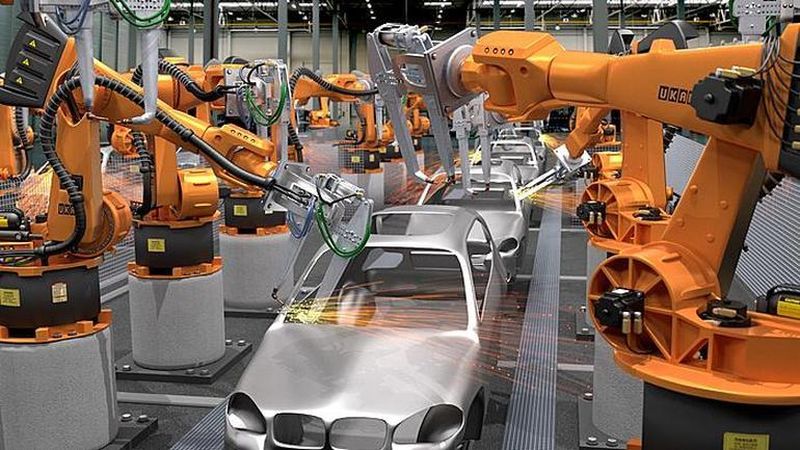

Automotive manufacturing industries have been employing robots in their production lines for over 50 years. Robots provide more efficiency, accuracy, and flexibility in various manufacturing processes including automaking. In fact, the automotive industry is among the top industries that use robotic automation in their manufacturing lines.

Every vehicle is composed of thousands of pieces and wires. Thus, the process of getting the components to their right positions is a complex one. In today’s discussion, we are going to give you the major applications of robots in automotive manufacturing. We will also include the reasons why automakers use industrial robots in their processes.

Applications of Robots in Automotive Manufacturing

As we have mentioned earlier, automobiles are composed of thousands of components. Making them will take different manufacturing processes. Advances in robotics technology in automotive manufacturing make robots suitable for automaking. These include force sensing and vision systems.

Below are the processes where industrial robots are used in automotive manufacturing:

1. Painting, Coating, & Sealing

The job of automotive painters is not that easy. Their task is very toxic. Moreover, labor shortages made finding skilled and professional painters more challenging. Robots can effortlessly complete the job because they can be programmed to provide consistent paints that cover large areas. This helps in limiting the waste produced. Robot arms are also suitable for spraying primers, sealants, and adhesives.

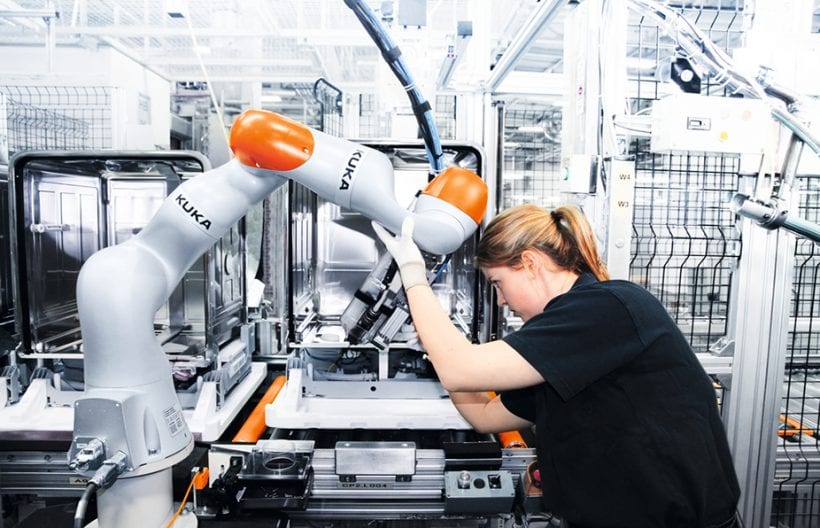

2. Machine Tending & Part Transfer

A lot of tasks in automotive manufacturing are too dangerous for humans. These include the following:

- Transferring molten metal into molds

- Moving metal stamps

- CNC loading and unloading

These types of work are ideal for large robots. Other loading and unloading tasks as well as machine tending are also done by industrial robots. For smaller operations, smaller cobots are more suitable.

3. Material Removal

Material removal processes can follow complex paths repeatedly. Thus, robots are more ideal for cutting and trimming tasks. These include:

- Polishing molds

- Cutting fabrics like headliners

- Trimming die castings and plastic molding.

Robots can maintain constant pressure in these kinds of applications with the help of force-sensing technologies.

4. Robotic Vision

Industrial robotic arms equipped with “eyes” provide more precise results. This is because they are able to “see” what they are doing. A robotic arm’s wrist can carry a laser and an array of cameras that allow the machine to have instant feedback.

Industrial robots today can perform precise offsetting during the installation of parts. They know where each part goes. Compared to regular robotic arms, robotic vision systems provide a more accurate installation of fenders, windshields, and door panels.

5. Assembly

In automotive manufacturing plants, tasks like wheel mounting, windshield installation, and screw driving are done by robotic arms. A lot of companies manufacturing automotive parts use robots, such as the Delta robot, to assemble smaller components like motors and pumps.

6. Arc Welding & Spot Welding

Large and long-reach robotic arms that can handle high payloads can be used to spot weld automotive body panels. On the other hand, smaller robots can weld subassemblies like mounts and brackets. Robotic metal inert gas (MIG) and tungsten inert gas (TIG) welding machines can position the torch in a single orientation on all cycles. Thus, they can maintain the consistency and quality of the resulting welds.

If you are looking for affordable and durable robotic arms that can help you perform various automotive manufacturing processes, you can go and check it here.

7. Internal Logistics

You can use automated vehicles in your factories to move materials from your storage area to your factory floor. Automated vehicles include Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and forklifts. One example application is using robots to deliver welding and industrial materials to different robot stations. This allows you to replace manual processes.

Why Automotive Manufacturers Use Robots

Automotive manufacturers use robots for a variety of reasons. But, the four main reasons are flexibility, safety, capacity, and quality.

1. Flexibility

Automated robots provide more flexibility compared to dedicated or hard automation in terms of the following:

● Less Changeover Time

You only need a flexible robot gripper design to load new programs into the robot.

● Fewer Obsolescence Risks

When one of your production lines disappears, you can still redeploy your robot with minimal additional costs. On the other hand, hard automation machines usually end up being thrown away.

● Ability to Deal With Product Families

Robots are flexible enough to instantly switch between different applications, whether it is for car assembly, spot welding, plastic molding, trimming, and others. By employing technologies such as vision systems and RFID tags in your robots, you can process multiple parts.

2. Safety

There are a lot of hazardous tasks in the manufacturing process of automobiles. Aside from the obvious dangers such as when pouring molten metal into molds, workers can also develop musculoskeletal disorders. Repetitive motions along with twisting and lifting are some of the tasks that can cause musculoskeletal disorders.

With robotic arms, the mentioned risks can be prevented. Automotive robots can help cut injuries and accidents by removing human workers from dangerous environments and tasks.

3. Capacity

Automotive manufacturers are aiming for process control and consistent times in every stage of the production. One small problem can cause your assembly line to stop running. Robots do not suffer from fatigue like humans so you will have constant cycle times all day. Plus, you will have consistent production rates.

#4 Quality

Automotive robots help in reducing variability in the parts produced. They never get distracted or tired and they are highly repeatable so they can produce uniform results in every cycle. Also, they do not drop or handle parts in a damaging way. This greatly reduces the errors in the automotive assembly.

Conclusion

Car manufacturing robotic arms give automakers a lot of competitive advantages. They can improve the quality of the parts produced, increase your production capacity, and eliminate bottlenecks. They are also programmable and are easier to deploy. However, make sure that you find an experienced partner if you are planning to adopt automotive robotics in your processes.