The manufacturing process in the automotive industry is long and hard. In order to cope with the flow of information, the automotive industry uses laser marking machines in order to label the products.

The manufacturing process consists of thousands of parts and each one if fabricated and handled to be assembled into an automobile. Each manufactured part needs to be delivered and installed into an automobile, and this is done through laser marking machines.

Laser Marking Codes

Laser marking machines give each car part a unique code that defines their function and location in the assembled car. The automotive industry relies on barcodes to define these laser marking codes, and every bit of information, such as location and function, is embedded on that barcode. The laser marking machines use laser beams to label these codes during the manufacturing part. It is entirely different to laser etching and engraving since this process digs and removes materials from the surface of the part.

Laser Marking Machines and their Use in the Automotive Industry

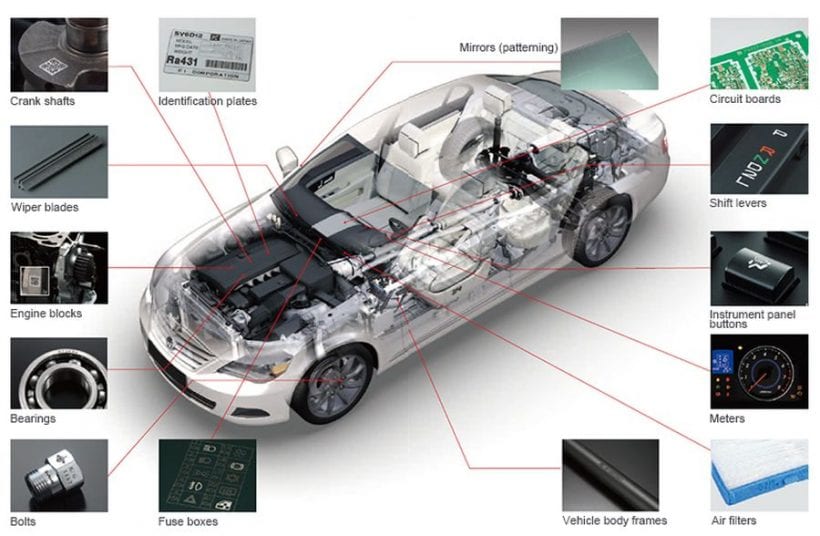

These machines have several very important uses in the automotive industry. The uses are the following:

• The numbering of parts and components of the engine

The first, and most common, use of laser marking machines is to label parts and components. The engine of the car is made out of sophisticated allows of steel that can withstand high temperatures. The components of the engine are being labeled with these marking machines by having QR codes placed on each component. Even the smallest of parts in the engine compartment is labeled. Parts such as bolts, bearings, and even nameplates, in the engine area are laser marked with numbers and barcodes since paper stickers can’t really withstand the hard temperatures that the engine reaches.

• Circuit boards

According to industry experts at HeatSign, printed circuit boards are mass produced prior to assembly. On these circuit boards, electronic components are the key components found on these silicon-based boards. Each layout of the circuit board is traced by laser marking machines, and the electronic components are later on soldered onto the boards themselves.

• Fuse Boxes

Laser marking machines are used to print diagrams and layouts on fuse boxes found on both the engine bay and inside the cabin. These diagrams and layouts are printed in order to serve as a guide for the owner and mechanics on which relays or fuses operate the corresponding electrical functions. Ink on paper doesn’t last long, so laser marking machines do this job way better.

• Instrument panel buttons

Each button and lever has a symbol that is directly printed onto them. If you take a look around the instrument cluster of your car, you will notice these buttons and levers. Laser marking machines are the ones responsible for that as well. We talk all the time about how ink or paint doesn’t last long, and it is precisely the reason why laser marking machines are so important to the automotive industry.

• Body frames and panels

Yet another part of the manufacturing process where laser marking machines are used is for labeling body frames and panels. Just like engine parts, body frames and panel require numbering and labeling for latter assembly. Ink and paint do a poor job, so laser marking machines are the best option.