Electric linear actuators have many users. The same is true for hydraulic and pneumatic options. The question, then, is, “Which one should you use?”

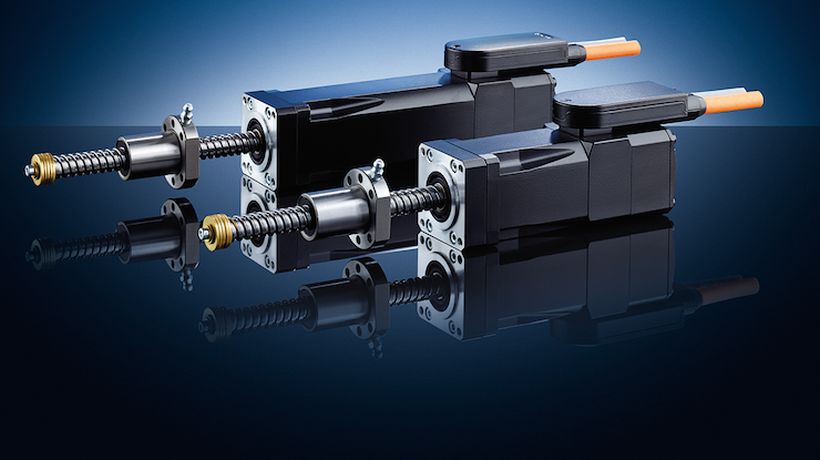

Each type has its pros and cons. You’ll need fluids and oils to use a hydraulic linear actuator. For a pneumatic one, power comes from pressurized gas or air. Meanwhile, electric motion devices use electricity, hence their name .

Electric linear actuators do have several advantages over hydraulic and pneumatic types. These advantages are what we’ll discuss in this post.

Why Electric Linear Actuators Are Better Than Hydraulic and Pneumatic Options

You get three main advantages when you use an electric linear actuator over the other two options. Check them out below:

● Higher Precision & Efficiency

In general, electrical devices are more accurate than hydraulic and pneumatic ones for many use cases. When it comes to motion devices, it’s not different. As a matter of fact, you get the best precision with electric linear actuators.

Pneumatic options sometimes suffer errors due to their design. Also, they react to vibration, which is common when operating many systems that use motion devices. All these affect the precision of the device.

With hydraulic types, you can expect somewhat more precision. The problem is that they sometimes suffer slack, backlash, and flex. And all these lower their accuracy. But with electric linear actuators, that’s not the case. You get more precision, thanks to their complete motion profile control.

Furthermore, it’s easier for electricity to stay stable than hydraulic fluids. Compared to pressurized gas, the advantage is even greater. And due to their stability, electric linear actuators are the best for tasks that need much repetition.

● More Flexibility

Electric linear actuators are easy to network and program. In simpler words, you can adjust them to fit different applications. So, electric actuators are, in a word, flexible.

For an actuator to fit its application, it must match certain fundamental factors. These usually involve loads, required speeds, and stroke lengths. If the device doesn’t meet the conditions, the system won’t work properly.

With this comes a problem with pneumatic and hydraulic linear actuators. Both types often support a low performance range. Meanwhile, electric types can handle different applications as they have less limits.

Their flexibility is one reason electric motion devices are more precise and adept As mentioned earlier, they support complete motion profile control. And that happens thanks to the integration with sensors, controllers, and feedback devices.

Furthermore, how often do you come across hydraulic fluids? Or pressurized gas? These power sources can be scarce and expensive to source in many areas. Meanwhile, you most likely use or encounter electricity every day and everywhere.

● Low Noise

Loud noise will make using a linear actuator a headache. As a matter of fact, it’ll make using any device uncomfortable. Without question, it affects your comfort, productivity, and health.

Suppose you’re working with others. In that case, the unwelcome sound will complicate communication and control. To avoid this, you need a low-noise device. And in that aspect, electric linear actuators are the best.

Electric devices can maintain a low noise level of up to 40 db. Some are even lesser, although it depends on the motor, drive system, and gearbox. Meanwhile, hydraulic types can reach up to 90 db. With pneumatic options, it’s worse, as they reach up to 100 db.

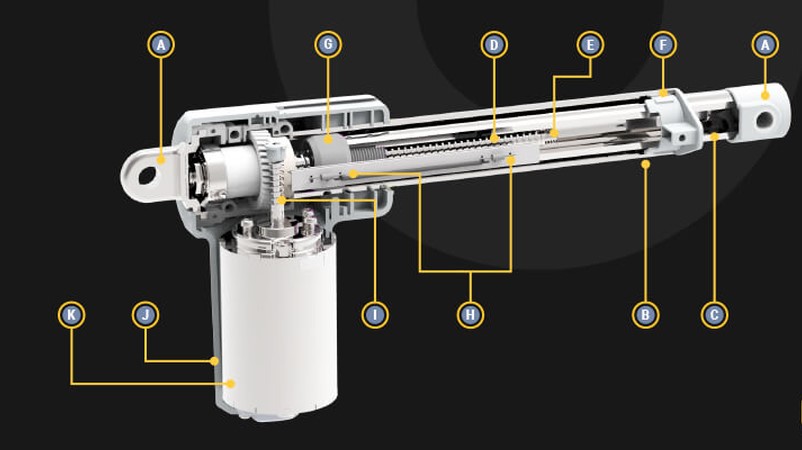

Electric actuators make less noise because they have fewer sound-making parts. In particular, they lack parts like pumps, valves, and compressors. Instead of these components, electric motion devices use a motor to generate power.

Fewer parts also means less vibration and friction. These two instances can increase noise. With pneumatic and hydraulic linear actuators, you get more vibrations since they feature many components. As a result, they create more noise, which is discomforting.

● Easy Maintenance

You must maintain your linear actuator to sustain its performance and reliability. How you do that differs from electric to hydraulic to pneumatic types. However, maintenance is a lot easier with an electric device.

As said before, electric linear actuator come with fewer parts. In other words, there are not many components to maintain, and that means less work.

With hydraulic and pneumatic devices, pumps, compressors, valves, and hoses come into play. Maintaining these parts is not so straightforward. And, sometimes, situations make it more difficult. For example, you may have to deal with leakages, clogging, and corroding. This also means the parts suffer more wear and tear.

Checking a hydraulic or pneumatic actuator for problems can be a puzzle. Consider a hydraulic device, for instance. You have to check the pressure, temperature, flow rate, and state of the fluid. The same applies to pneumatic options if you switch fluids for air supply.

If you use an electric linear actuator, you can worry less about the above. You’ll often only have to inspect the wiring, alignment, and insulation. Also, thanks to immediate feedback, detecting failures is easy.

● Better Safety

From the previous advantages, it’s easy to see why electric linear actuators are safer. Hydraulic devices use fluids and oils, which can cause contamination if they corrode. Besides, these fluids are usually flammable. And with that comes the possibility of fire hazards if there’s a spill.

With electricity, there’s also the risk of fire hazards. Another concern is electric shock. Even so, these dangers are less likely to happen thanks to quality insulation.

Pneumatic linear actuators come third when discussing safety. They’re less secure since gas leakages are more dangerous. Considering the extreme pressure and compression the gases endure, an explosion could ensue.

Summary

Electric linear actuators top hydraulic and pneumatic options in many areas. These include efficiency, precision, flexibility, maintenance, and safety. Thus, as stated, you’re not making a wrong decision if you pick these electric devices.

In some cases, you won’t be making the right decision. Electric linear actuators are versatile and flexible, as explained. But hydraulic and pneumatic types will suit some specific applications better. So, all in all, consider your project when deciding which linear actuator type to use.