If you’re an off-road enthusiast or if you live in an area with a lot of trails, you’re probably aware of the advantages a proper four-wheel-drive system brings to the table. However, old-school off-roaders are a lot more complicated underneath than you may think even though almost everything is mechanical.

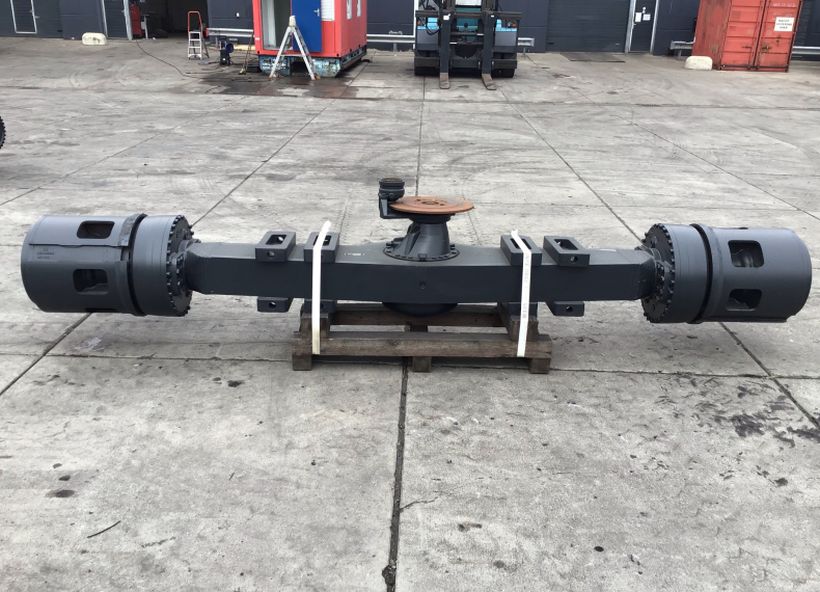

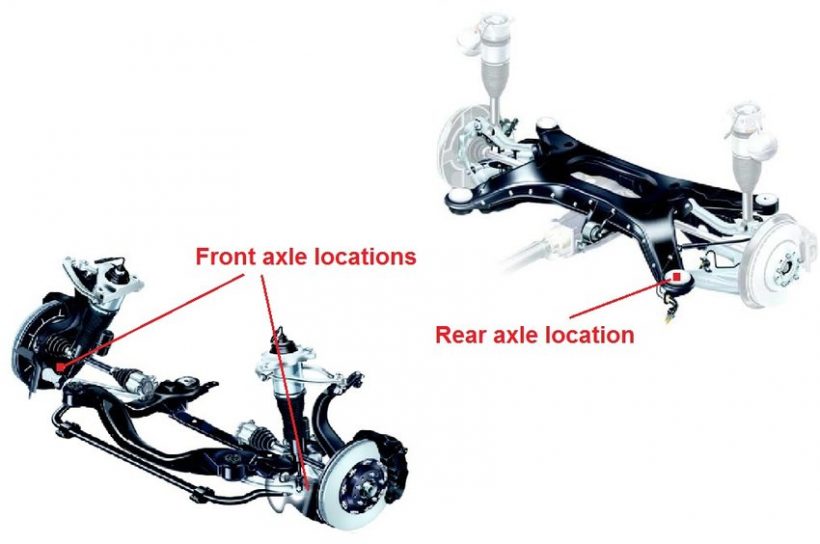

Unlike the rear axle which is tasked with delivering the power to the driving wheels, the front axle is a lot more complicated. Since the steering components are connected to the front wheels, the front axle has to deal with steering assist and absorbing shocks. The front axle has four main parts which include the beam, track rod, swivel pin, and stub axle. For extra reliability and ruggedness, front axles are usually made from carbon steel or nickel steel.

Furthermore, there are two types of front axles in general. With a dead front axle, the axles don’t rotate with the wheels and have separate housings to protect them from water and dirt. A live front axle on the other hand directly delivers power to the front wheels from the gearbox.

If you’re unsure about which one your car uses and want to know more technical details about your car, a car selling website like CarIndigo or Cargurus can be browsed, that contains all the required info to help you out.

With the rise of modern crossovers, sales of body-on-frame off-roaders have declined considerably. Unlike the all-wheel-drive system found in these crossovers that use a simple transfer case and only send power to all wheels when the need arises, proper four-wheel-drive models use axles at the front and rear, to transfer power to all wheels all the time. Many also get lockable differentials. If your axle is in disrepair, you’ll notice symptoms like a loud clunk when a gear is engaged, excessive vibrations, and as a worst-case scenario, the car won’t move forward or backward.

Unfortunately, due to their dwindling popularity, off-road parts like axles, transfer cases, and more have become a lot more expensive and hard to find. If you need a replacement front axle, here are 10 tips to help you find a good front axle:

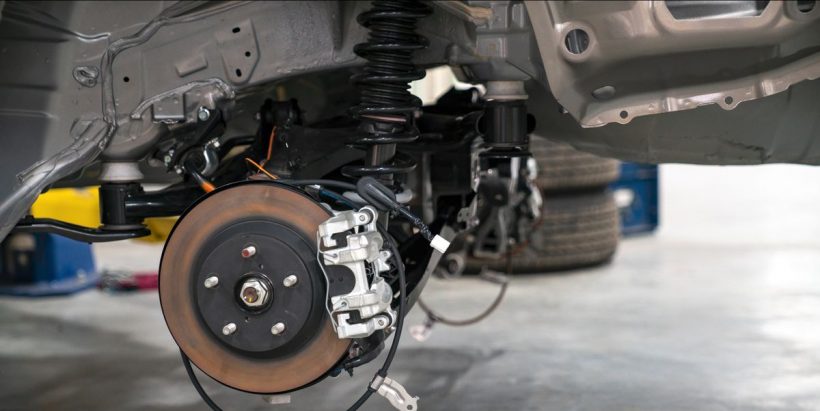

Brakes

- As expected, brakes are the most important component in a vehicle, and they are directly mounted to the axle. If the axle is left unused for a while, it will easily develop rust and other corrosion on the braking hardware like the rotors, making them unusable in some cases. The caliper is also susceptible to damage, so thoroughly check the piston boots for any tears and leaks. If the rotors are rusted, they should be replaced. Also check if the axle was stored without the caliper, as water and other contaminants may enter the caliper.

Hubs and bearings

- The next important part to check is the hub. If the axle is equipped with locking hubs, try turning them around and make sure the hub engages easily. If it doesn’t spin, do some further investigation and take off the locking hub to check if there’s any damage. Propping up one end of the axle should allow you to turn the hub freely.

Wheel mounting surfaces

- Mounting surface issues will be a lot more apparent on axles that have been sitting outside for a long time. While this may seem simple at first, some early models of Jeep had reversed lug nut threads that tighten to the left. Since this is very rare in the motoring world, some workshops may have damaged it or the replaced studs may be in the wrong direction.

- So check all the studs for damage and if they have been replaced properly. The last thing you want is a wheel falling off on your off-road adventures. Using wheel spacers may also damage the mounting surfaces.

Spindles

- When checking the wheel hubs, also keep an eye out for damaged spindle threads and ends. Spindle damage is most apparent on models with bearing damage. If the spindles are generally clear without any cracks or wear, they should be fine. But, any bearing damage will cause pitting and scoring on the spindle, leaving a blueish mark.

Axle housing

- In most cases, spare axles are not mounted on vehicles, making it harder to spot any bends or other issues when driving it. Carefully check the axle for any damage, and if there are any camber adjustment shims between the spindle and steering knuckle. These are commonly used to help the vehicle track straight, and usually indicate bending or other damages.

Steering linkages

- Unlike the rear axle, the front axle also has to deal with steering the car, making them more complicated. This means the tie rod ends and other steering-related components are mounted on the front axle and should be checked for damages. Check for any modifications to the steering linkages. If they have spherical rod ends or improperly sized tie-rods, the mounting holes will be damaged and need to be re-tapered or drilled for bigger bolts. If there is any damage, make sure there’s enough material left to accommodate bigger diameter bolts for future repairs.

Ball joints

- Like most passenger cars, ball joints should also be thoroughly checked before buying a front axle. If the axle is already on a car, jacking it up and checking for wheel movement or play is an easy way to find worn-out ball joints. You can also use a pry bar under the tire and push up to notice any independent movement. However, if the axle is not installed, diagnosing it is a lot harder. Check the rubber boots for any tears or leaks, and peel them back to check for rust.

Axle shafts and U Joints

- The easiest way to check for axle shaft damage is by making sure the C-clips are present and the caps are secured. Another way to check is by pulling on the shafts to check for play. The splines and other sealing surfaces should also be checked for damage. If there is excessive scoring, the gear lube will start to leak as you start using your new axle.

Ring and pinion

- An easy way to check the rack and pinion condition is to check for play by grabbing the yoke and moving it clockwise and counterclockwise. If there is excessive play, the next step is to take apart the diff cover and inspect the gear lube for metal flake, indicating wear.

Differential

Finally, we reach the end of the list at one of the main components on the axle. Differentials usually make up most of the cost when reconditioning a front axle due to the mechanicals and components involved. Lockers and limited slips can be very expensive. Depending on the type of axle, there are different ways to check.

For air lockers, you’ll have to rig up a source of air to check if they lock. Checking auto lockers is the hardest, and you have to lift the car and hold the other wheels while turning one of them. As a worst-case scenario, you’ll have to disassemble the differential and its components and do a thorough check.