Throughout the years, industrial robots have achieved a great deal of innovation and sophistication. Nowadays, industrial robots are extremely accurate and can even perform functions with more skill and speed than a human worker.

So, if you own a car repair business, it is the high time that you consider using industrial robots in your operations instead of hiring human auto repair workers.

Here are the main reasons why you should use industrial robots in your car repair business:

1. No Need to Train New Workers

One of the biggest advantages of having your operations automated is that you no longer need to train new workers. Training new employees takes a great deal of time and resources. You will have to invest a lot of attention on them, and there are chances they will make mistakes: these will cost you time and money.

Industrial robots on the other hand, are designed to fulfill their duties once you get them out of the box. All you need to do is to upload their programs, and you will have them working in no time.

2. Single-Minded Efficiency

Industrial robots are designed to fulfill specific tasks. They are single-minded when it comes to fulfilling these tasks, and can do them with incredible efficiency. Human workers, no matter how experienced, can get distracted every now and then. With an industrial robot, you will have unerring efficiency every time.

Whether they are putting on a new coat of paint on a car or calibrating its suspension levels, it is important that your car repair business delivers excellent service every time. Overall, industrial robots are a welcome addition to your business.

3. Faster Repair Speed

When it comes to running a car repair business, speed is key. Remember, cars are essential to getting around, and all clients would want their cars fixed promptly. It is during times like these that you will have to put in extra hours of work.

With human workers, you have to pay them for the extra time. Humans are also prone to fatigue. This means that as time goes by, your workers’ efficiency may go down.

Industrial robots on the other hand can work for hours on end without any signs of fatigue. By using customized robots, fewer mistakes will be made, and repairs will be done faster.

4. No Need to Pay for Insurance or Other Health Benefits

All employees deserve to get insurance and health benefits. From a business perspective, however, insurance and health benefits cost money.

If most of your operations are done by industrial robots, then you won’t have to pay for these expenses. Instead, you can utilize the funds saved to further modernize your car repair business.

5. Eliminates Human Error

One of the best reasons why you should use industrial robots in your car repair business is that it eliminates human error. There will be days where some car repair workers are on top of their game, but there will also be times where they make mistakes.

With industrial robots however, they are specially configured to be as accurate as possible. They can be programmed to do a specific task, and they will do it as consistently as possible. By keying in the proper commands, the robot will execute the task at hand with unerring accuracy.

6. They Can Do All the Heavy Lifting

Industrial robots have a definite advantage over human workers when it comes to physical force. This makes them perfect for tasks that require great physical strength.

No matter what type of industrial robot you use, they are capable of doing most of the grunt work in your car repair business. All in all, you can be assured that all the physically demanding jobs will be taken care of.

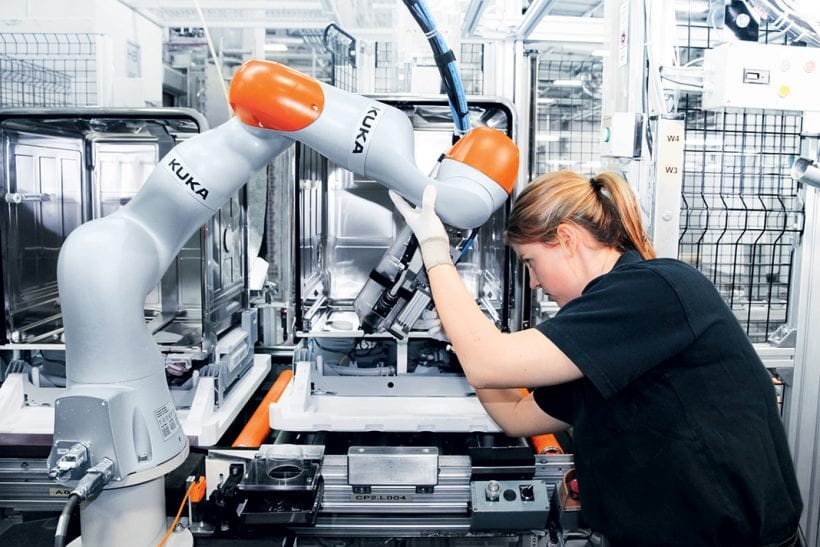

7. They Are Perfect for Mechanics to Work With

Aside from the efficiency that industrial robots bring to the car repair process, they are also a great help to your mechanics. Although industrial robots are incredible when it comes to specific tasks such as changing tires and calibrating hydraulics, they are still somewhat behind seasoned mechanics when it comes to diagnosing a car’s problem.

As such, you should still have a core group of experienced mechanics that will diagnose the problem. The industrial robot’s part in the repair process is that they will implement all the mechanic’s instructions with as little fuss as possible. This is a great partnership that will ensure your car repair business offers the best repair services possible.

Conclusion

Repairing a car is high-precision work, and there is a wide margin of error. With the help of industrial robots, you will be able to eliminate the chances of human error and speed up your repairs.

Ensuring that all your machines are of the best quality and properly maintained is key as breakdowns and repairs can be costly for your business. Luckily there are companies such as EVS that not only create robots but repair them as well. Visit here and have your pick of the best-quality industrial robots in the market.