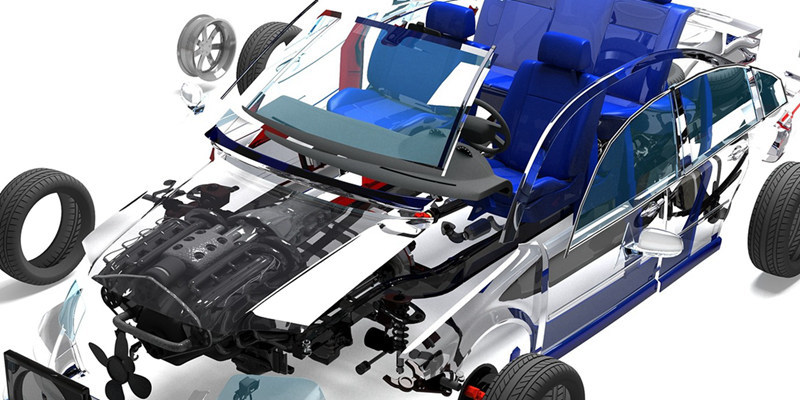

With its unmatched precision and versatility, laser cutting technology has completely changed the manufacturing of custom automotive parts. Whether you operate as a professional fabricator or highly experienced in doing it yourself, laser cutting will help you succeed tremendously with your projects. In this extensive blog, we will review the top tips for creating custom car parts that slickly combine aesthetics and functionality using laser-cutting technology.

So, without wasting much time, let’s get started.

1. Understand laser-cutting technology

Before getting into the specifics of creating custom car parts, it’s essential to understand the fundamentals of laser cutting and micro hole drilling because they are essential processes when it comes to creating custom cart parts.

Using a powerful laser beam, laser cutting creates accurate cuts in materials like wood, plastic, and metal. Because the procedure is computer-controlled, precision down to the last detail is guaranteed.

2. Describe the goal of your project

Establish the goal of your custom car parts before you start the design and construction process. A clear vision will direct your design decisions and guarantee that the final product satisfies your objectives, whether they are related to performance, aesthetics, or meeting a particular need.

3. Do extensive research

Take a deep dive into the world of automotive design. Examine current aftermarket automotive components, collect ideas from many sources, and recognize patterns. In addition to stimulating your creativity, this research phase will provide you insights into what functions and forms well.

4. Select the right material for the laser-cutting

Many different types of materials, each with unique qualities, can be cut with a laser. While selecting materials, keep things like strength, weight, and aesthetics in mind. Typical choices of materials include the following:

Aluminum: Suitable for various components, it is lightweight and sturdy.

Acrylic: Transparent acrylic is perfect for interior detailing.

Stainless steel: Offers durability and a sleek, contemporary appearance.

Take detailed measurements

Custom automotive parts that are laser-cut are known for their precision. Measure the spaces carefully where the items are going to be put. Ensure your specs are accurate, accounting for the design’s curves, angles, and fine details.

5. Use CAD software to come up with a plan

Use Computer-Aided Design (CAD) software to generate a comprehensive plan for your custom automobile parts. Pay close attention to every detail since the precision of the final laser-cut parts is closely correlated with the correctness of your CAD design. Transform your artwork into a vector file that the laser cutter can read.

6. Consider fitment and tolerance

To guarantee a flawless fit, take tolerances into account when designing. Remember that different materials could need different tolerances, so keep things like thermal expansion and contraction in mind. Achieving ideal fitment will be aided by iterative testing and modifications.

7. Try out some design complexity

Complex designs are easily handled by laser cutting technology. Try out intricate designs, textures, and shapes that would be difficult or impossible to accomplish with conventional manufacturing techniques. Push the limits of design while considering practicality.

8. Make the most of laser cutting

Vector trajectories are the basis for how laser cutting works. Reduce redundant elements in your design and streamline curves into clean routes for optimal results. This improves the end product’s cleanliness and shine while also increasing the effectiveness of the laser-cutting process.

9. Make good use of prototyping

Make prototypes of your own vehicle parts before committing to a complete production run. Using a prototype, you can verify the design, check fit, and make any required changes without worrying about damaging pricey materials. It’s an essential stage in the process of iterative design.

10. Select the proper laser cutting machine

It’s crucial to choose the right laser-cutting machine. Take into account elements like bed size, laser power, and material compatibility. The creating process will operate more precisely and efficiently with the help of a suitable machine.

11. Master laser cutting parameters

Optimizing laser cutting parameters is crucial to getting the best possible results. To discover the ideal balance for your design’s particular material and complexity, experiment with different cutting speeds, power levels, and focal lengths.

12. Integrate aesthetics and function

Although functionality is important, don’t let aesthetics suffer. Make sure your custom car parts perform as intended in addition to having a lovely appearance. Parts that combine style and functionality will improve the vehicle’s look and performance.

13. Pay close attention to the final finishing

Post-processing may be necessary for laser-cut pieces, depending on the material. To get the required appearance, take into consideration surface finishing processes like painting, polishing, or anodizing for metals. Pay close attention to details that improve the finished product’s overall attractiveness.

14. Document every step

Make sure you have detailed records of the design and manufacturing process. This covers machine settings, CAD files, and any difficulties that may have arisen. Gaining knowledge from every project guarantees ongoing progress and simplifies subsequent undertakings.

15. Don’t neglect safety

High-powered lasers and possibly dangerous materials are often used in laser cutting. Put safety first by putting on the correct protective gear, ensuring enough ventilation, and adhering to all safety instructions supplied by the manufacturer of the laser-cutting machine.

Conclusion

Learning how to create unique car components with laser cutting requires a combination of technical proficiency, artistic vision, and dedication to accuracy. With these tips mentioned in this article, experts and amateurs may fully use laser cutting technology to produce distinctive, premium custom car parts that are not only exceptional in appearance but also functionality. Embrace the possibilities, push the boundary of creativity, and enjoy the satisfaction that comes with creating car parts that meet your needs.