Diesel engines are renowned for their power and efficiency, making them popular for various vehicles and machinery. However, to ensure peak performance and longevity, it is essential to prioritise regular maintenance. We will explore the key maintenance tasks for running your diesel engine smoothly and efficiently. Diesel Dynamics offers a comprehensive guide to maintaining your diesel engine for optimal performance, from changing filters and monitoring fluid levels to addressing potential issues before they become significant problems.

The Role of Specialized Fluids in Emission Control

Specialised fluids play a critical role in emission control for diesel engines, as they help reduce harmful pollutants released into the environment. To effectively control emissions, it is essential to maintain optimal levels of diesel exhaust fluid among other specialised fluids within the engine system. Failure to do so can lead to increased emissions levels, which not only contribute to environmental pollution but can also result in poor engine performance.

In addition to the environmental impact, inadequate levels of specialised fluids can also significantly impact the vehicle’s overall performance. Diesel engines may experience reduced fuel efficiency, increased emissions, and potential engine damage without proper maintenance. By understanding the importance of maintaining optimal fluid levels, vehicle owners can ensure that their diesel engines operate at peak performance levels, providing greater power and efficiency while minimising their environmental footprint. Regular monitoring and maintenance of these specialised fluids are crucial for the longevity and efficiency of diesel engines, making them essential for engine maintenance.

The use of specialised fluids also aids in meeting regulatory requirements for emissions control. Many countries have stringent emissions standards that diesel vehicles must adhere to, and proper maintenance of these fluids is often a key component of compliance. Failure to meet these standards can result in fines or penalties for vehicle owners, highlighting the importance of incorporating specialised fluids into regular maintenance routines. Vehicle owners can avoid costly repercussions while promoting environmental sustainability by staying ahead of regulatory requirements through proper fluid management.

Regular Oil Changes for Longevity

Regular oil changes are crucial to diesel engine maintenance to enhance longevity and efficiency. Oil acts as a lubricant for the engine components, reducing friction and heat buildup that can lead to premature wear and tear. Regularly changing the oil ensures the engine is well-protected and running smoothly, extending its lifespan.

Timely oil changes also help to remove contaminants and debris that can accumulate in the oil over time. These contaminants can cause damage to the engine if left unchecked, compromising its performance and efficiency. By staying on top of oil changes, you can prevent these issues and keep your diesel engine operating at its peak performance level for years. Investing in regular maintenance, including oil changes, is an essential step in ensuring the reliability and longevity of your diesel engine.

In addition to protecting the engine from wear and tear, regular oil changes also contribute to maintaining optimal fuel efficiency. Fresh, clean oil reduces friction between moving parts, allowing the engine to operate more efficiently and consume less fuel. Over time, old oil can thicken and become less effective at lubricating engine components, increasing friction and fuel consumption. By adhering to a consistent oil change schedule, diesel engine owners can prolong the engine’s lifespan and enjoy improved fuel economy, ultimately saving on fuel costs in the long run.

Fuel System Care

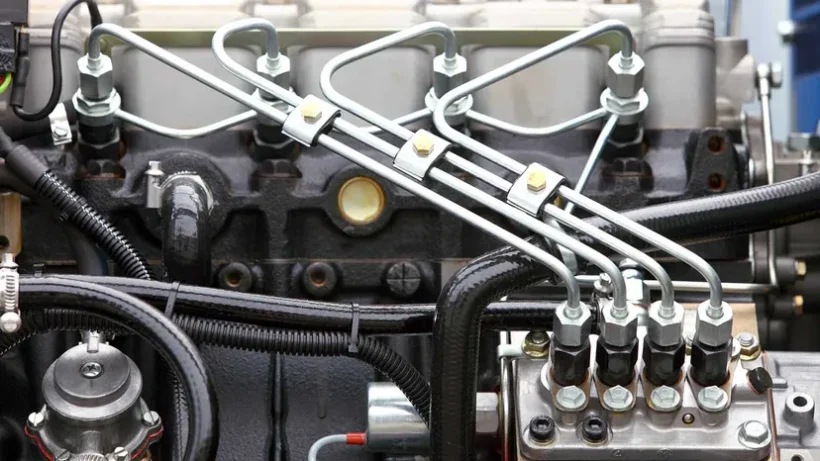

Maintaining a clean fuel system is essential for adequately functioning a diesel engine. Common contaminants such as water, dirt, and debris can clog fuel filters, injectors, and pumps, leading to decreased performance and potential damage to the engine. It is important to use high-quality fuel from reputable sources and regularly inspect and replace fuel filters to prevent these issues. Using fuel additives can help to clean and lubricate the fuel system, improving overall performance and efficiency.

In addition to focusing on fuel quality, it is essential to regularly inspect and clean other fuel system components, such as the fuel tank and lines. Moisture and debris can build up in these areas, leading to corrosion and blockages that can impact the engine’s performance. By implementing a regular maintenance schedule that includes thorough inspections and cleanings of the fuel system, you can help to ensure that your diesel engine operates at peak performance for years to come.

Proper fuel system care extends beyond just the fuel itself; it also involves attention to the entire fuel delivery system. This includes regular inspection and maintenance of fuel tanks, lines, and connections. Over time, corrosion, leaks, or blockages can occur, hindering the flow of fuel to the engine and compromising performance. Regular inspections and proactive maintenance help identify and address these issues before they escalate, ensuring the fuel system remains clean, efficient, and reliable. By prioritising comprehensive fuel system care, diesel engine owners can optimise performance, minimise downtime, and extend the lifespan of their engines, ultimately maximising their investment and reliability.

Turbocharger Maintenance for Enhanced Power

Turbochargers play a vital role in enhancing the power output of diesel engines. However, their efficiency and lifespan can only be protected with proper maintenance. This subsection delves into the importance of regular inspection, cleaning, and lubrication of turbocharger components to ensure optimal performance. It discusses standard turbocharger issues and offers preventative maintenance tips to prolong their lifespan and maintain peak engine efficiency.” Use an engaging tone and only use known facts.

Turbochargers serve as the powerhouse behind diesel engines, significantly boosting power and efficiency. However, like any mechanical component, they require regular care and maintenance to operate at their best. Neglecting turbocharger upkeep can lead to decreased performance, increased fuel consumption, and even costly repairs down the line.

Regular inspection is crucial in identifying potential issues before they escalate. Checking for signs of wear and tear, such as oil leaks or abnormal noises, can help catch problems early on. Additionally, ensuring proper lubrication of turbocharger bearings and shafts is essential for reducing friction and heat buildup, ultimately extending the lifespan of the turbocharger and maximising engine performance.

Keeping the turbocharger and its associated components clean is paramount. Over time, dirt, debris, and carbon deposits can accumulate, reducing airflow and increasing strain on the turbocharger. Regular cleaning of intake systems and air filters helps maintain optimal airflow, preserving the efficiency of the turbocharger and preventing premature wear. By incorporating these maintenance practices into a regular servicing routine, diesel engine owners can ensure their turbochargers continue to deliver enhanced power and efficiency for years to come.