The Protection board/BMS plays a very important role in the lithium battery pack, especially for the electric vehicle. During the lithium battery design process, the corresponding protection board or BMS must be used for reliable design. It can even assist the quality section to analyze abnormal batteries or circuits together. From the technical research and practice from SmartPropel, we accompany with them to introduce the principle and purchasing skills of the electric vehicle protection board/BMS.

The main components of lithium-ion batteries

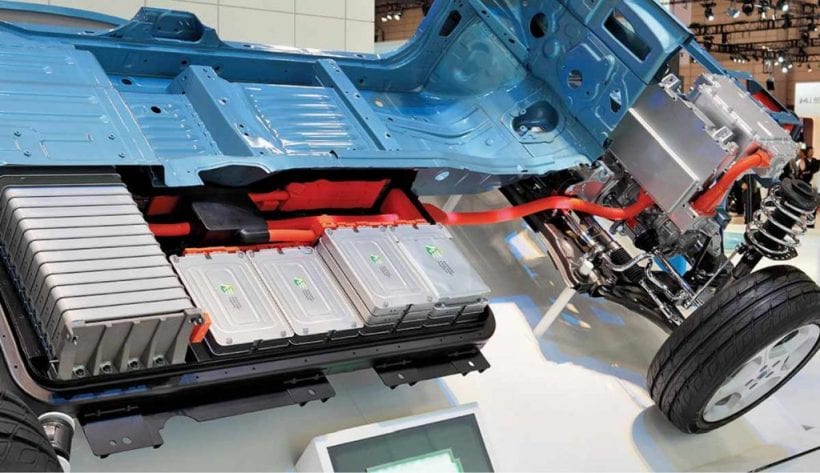

The lithium battery is consists of two main parts, battery cells and protection board (for power battery is generally called BMS). The battery cell is the heart of the lithium battery, while the management system is the brain. The cell mainly consists of anode material, cathode material, electrolyte, diaphragm, and shell, while the protection board(can also called guard plate) mainly consists of protection chip (or management chip), Mos tube, resistance, capacitance, and PCB board.

Lithium batteries need to be protected because of their characteristics. Because Lithium batteries self-material can not be overcharged, over-discharged, over-current, short circuit or overcharged or discharged at very high temperatures. The lithium battery pack is always assembled with elaborate guard plate and a piece of current fuse.

The function of the protection board (or BMS) is usually accomplished by protecting circuit board and PTC, etc. It is composed of the electronic circuit, which can accurately monitor the voltage and current of charging and discharging circuits of the battery at-40 °C to + 85 °C, timely control the current circuit, PTC can prevent the battery from serious damage in a high-temperature environment.

We often use the guard plate and BMS for battery. What is the difference between them? How to choose them?

Generally speaking, continuous discharge current less than 200A, battery maximum voltage does not exceed 100V, customers don’t have battery communication function and other special requirements, you can choose the guard plate. However, when the continuous discharge current is more than 200A, the battery maximum voltage is more than 100V, and the customers need communicate function, BMS is usually be chosen to be used in the battery.

How to select and measure the performance of the protection board

1. Common Equalizing Function: A. Terminal equalizing function; B. Voltage difference real-time equalizing function

The equilibrium current is generally 30 ~ 100 mA. The Heating Temperature of the equalization circuit does not exceed 40 degrees.

2. Temperature detection and protection

1)The protective board charge normal temperature range 0 ~ 45℃, beyond the normal temperature range then stop charging, temperature detection accuracy is ± 5℃. Optional charging high temperature 45℃ ± 5℃ protection.

2)The guard plate discharge normal temperature range 20℃ ~ 60℃, outside the normal temperature range then stop discharge, temperature detection accuracy is ± 5℃. Optional discharge high-temperature protection of 65℃ ± 5℃.

3. Overcharge protection

1)Lithium cobalt oxide battery and NCM battery, single-cell overcharge protection voltage is 4.20-4.25 V, accuracy is 25 mV.

2)Lithium Iron Phosphate battery, the single-cell overcharge protection voltage is 3.70-3.90V, accuracy is 25mV.

3)Lithium titanate battery, the single-cell overcharge protection voltage is 2.80V-2.90V, accuracy is 50mV.

4. Over-discharge protection

1)Lithium iron phosphate battery, the over-discharge protection voltage is 2.0-2.5V, and accuracy is 80mV.

2)Lithium cobalt oxide battery and NCM battery, the over-discharge protection voltage is 2.5-3.0 V, accuracy is 80mV.

3)Lithium titanate battery, the over-discharge protection voltage is 1.4-1.5 V, accuracy is 80mV.

5. Over-current protection

1)The discharge over-current protection is available, and its is defined according to the specific item.

2)The charge over-current protection is available, and its delay value is defined according to the specific item.

6. Short circuit protection

The output short-circuits protection is available, and its delay value is defined according to the specific item.

7. Power consumables

1)Common hardware protection board, consumable power requirements < 100uA.

2)Protection board with power communication and other special functions, self-consumption requirement < 200uA. For self-consumption > 200uA special items, engineers adjust the requirements according to the items.

8. Conduction resistance

Guard plate conduction resistance according to the specific product definition, the full load temperature rise is less than 40℃.

9. Continuous current

1)Rated continuous discharge current, all components temperature rise less than 40℃.

2)Maximum continuous discharge current, working at maximum continuous discharge current without protection for 20 seconds, all components temperature rise less than 50 ℃.

3)Continuous charging current, all components temperature rise less than 25 ℃.

10. Temperature rise

The maximum temperature rise of heating elements such as resistors and MOS is less than 50 °C, so as to discharge and charge the maximum current that can work continuously.

11. Output Anti-reverse function

Optional guard plate output with anti-reverse connection function.

12. Withstand voltage

When the charging voltage of the input terminal is 1.2 times higher than the normal charging voltage, the guard plate must not be damaged.

13. Fuses

The fuse is added to the circuit. The fuse current is 1.25-1.7 times than the normal working current and can not be turned off when the PCM is over-current protected.

For BMS, except for the protection board function description, it has more functions

The general BMS has diversity functions, which can be adjusted flexibly depending on the project situation.

1. Heating management (high and low-temperature detection and protection). Most low-temperature project may need apply heating management system. For overall heat dissipation, should use air or water cooling as much as possible.

Equilibrium management. There are active equilibrium and passive equilibrium, and active equilibrium is the first choice for large capacity products.

2.Capacity calculation SOC. Dynamic SOC is estimated by integrating current with battery discharge curve, load voltage, and current. Power battery should be controlled within 10% error, energy storage battery should be controlled within 5% error.

3.Alarm alert. Display all kinds of battery information (voltage, current, temperature, SOC, charging state, charging fault, etc.) on the display screen, also can be transmitted to the host computer through communication. When there is a fault, the buzzer will give an alarm to the user, the specific type of fault is displayed on the display screen at the same time, also can be adjusted according to the requirements of customers and the project actual situation.

4.Power detection. Generally, the operating conditions should be uploaded to the host computer for analysis.

5.Voltage detection. By isolating and amplifying the series cells voltage, fulfill the real-time detection of individual cell voltage, the voltage detection range is 0 ~ 5V, the detection accuracy is ± 5mV.

6.SOC & SOH State Detection. The battery health status can be analyzed according to the various performance indexes.

7.Display System. Can display voltage, current, temperature, SOC, charging state, charging failure, etc.

8.Communication Function. Design communication types and functions according to customer requirements.

9.Electric leakage detection.

10.Best charging current control.

11.System self-check.

Through the above information, I guess you must have a better understanding of the protection board and BMS. In a word, They both play an important role in the battery pack to ensure the battery pack safety and long cycle life. BMS is an upgraded version based on the guard plate, with a higher price. Manufacturers will select the most suitable protection board or BMS according to the project indeed requirement.